Inventory management and tracking in retail stores

Barcode labels play a crucial role in ensuring smooth inventory management and tracking in retail stores. They facilitate efficient stocktaking, reorder management, and pricing. Through the use of barcode scanning, retailers are able to quickly access product details and maintain up-to-date inventory records. This helps to ensure precise stock levels and minimise the occurrence of out-of-stock scenarios.

Asset tracking in offices and businesses

Barcode labels can be used in a range of office environments to efficiently track assets within offices and businesses. Every asset, including computers, furniture, and equipment, can be assigned a distinct barcode label. By implementing this form of system, your businesses can effectively monitor the whereabouts, state, and maintenance records of their assets, resulting in enhanced asset management and reduced risks of loss or theft. Asset tags with barcodes are a convenient and accurate way to track items that may not have a suitable surface for traditional sticker labels.

Barcode ticketing and access control for events or transportation services

Barcode labels are widely used for ticketing and access control at events or transportation services. These labels enable scanning for ticket validation and access, ensuring a seamless and streamlined process for attendees. Barcode labels offer a reliable and user-friendly solution for effectively managing ticketing and regulating access to venues or transport services.

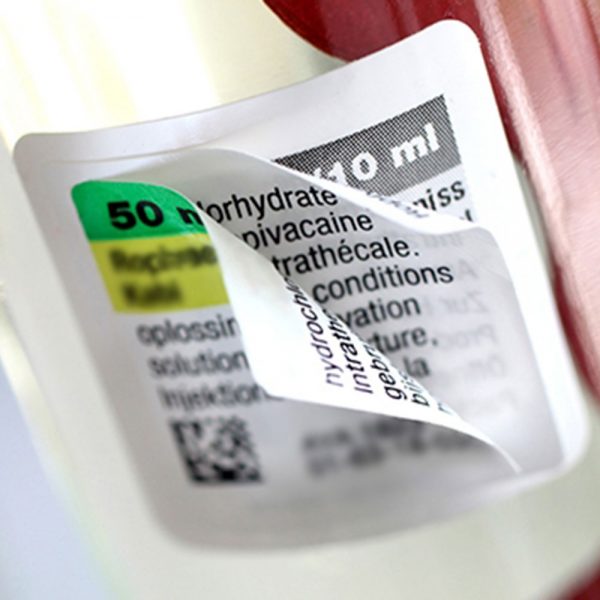

Medical specimens and patient tracking in healthcare facilities

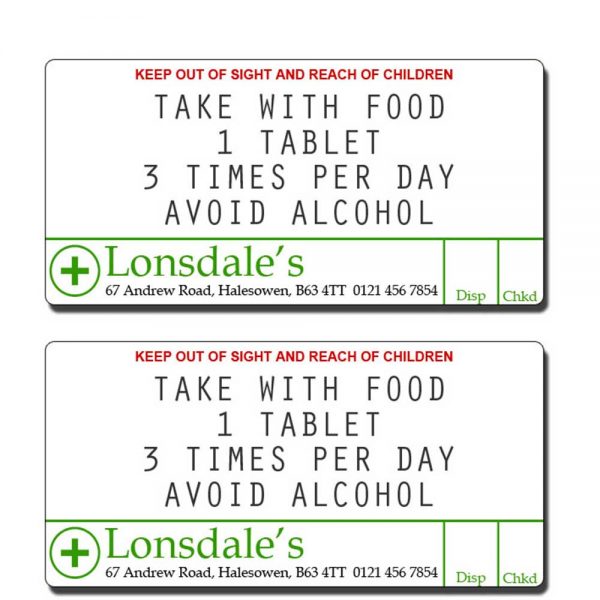

Barcode labels play a vital role in healthcare facilities, enabling efficient tracking of medical specimens and patients. Every specimen or patient can be assigned a distinct barcode label, ensuring precise tracking and identification. Barcode labels are essential for optimising various processes, including specimen collection, laboratory testing, and patient administration. By using these labels, healthcare facilities can enhance patient safety and improve the overall efficiency of their operations.

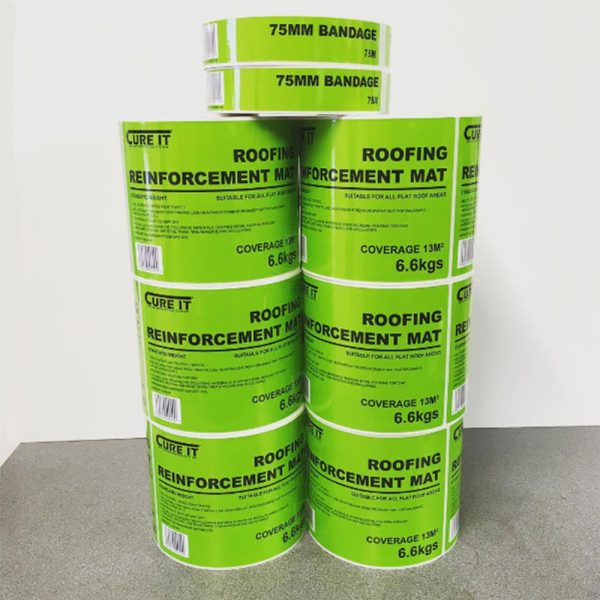

Product identification and tracking in warehouses and distribution centres

Barcode labels are essential in warehouses and distribution centres as they enable easy identification and tracking of products.

Every product can have its own barcode label, which allows for streamlined inventory management, order fulfilment, and shipment tracking. Barcode labels are essential for optimising operations, minimising mistakes, and guaranteeing precise inventory management, resulting in improved efficiency and cost savings for warehouse management.

Frequently Asked Questions

How do I choose the right barcode label for my product?

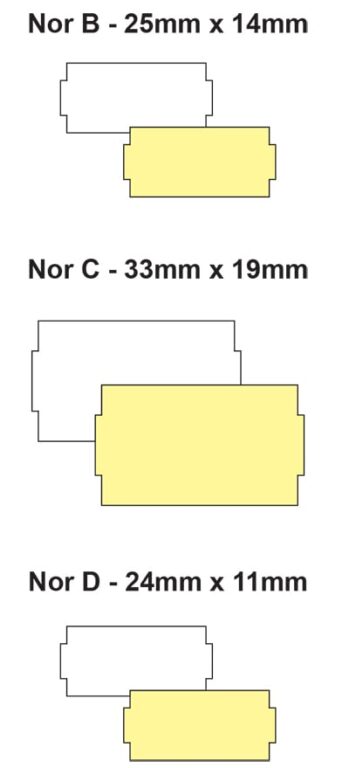

When choosing a barcode label for your product, consider factors such as the barcode symbology (e.g., EAN), label size, material, and finish that best suit your product and packaging. The label should be scannable and durable to withstand the product’s environment.

Can I order labels in custom shapes and sizes?

Yes, barcode label providers offer the option to order labels in custom shapes and sizes to meet your specific requirements. Whether you need round, square, rectangle, or unique-shaped labels, custom options are available to ensure a perfect fit for your product packaging.

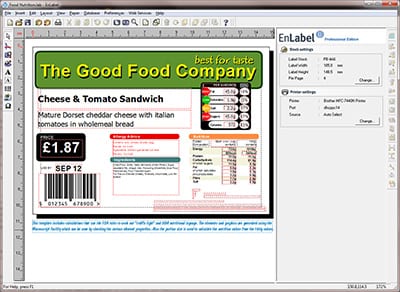

Can I make my own barcode labels?

While it is possible to print your own barcode labels using specialised barcode label printers, it is recommended to use professional barcode label printing services such as ours, for accurate and high-quality results. Only comprehensive barcode label printers have the expertise and equipment necessary to ensure optimal barcode readability and durability.

How do I generate a barcode sticker?

To generate a barcode, you can use barcode generation software or online barcode generators. These tools allow you to input the desired information (e.g., product code) and generate a barcode image in the chosen symbology (e.g., EAN). The generated barcode can then be incorporated into your label design.

What are the different types of barcodes you can print on the labels?

Barcode labels can be printed with various types of barcodes, including EAN-8 and EAN-13 codes. EAN barcodes are commonly used for product identification and tracking, with EAN-8 codes having 8 characters and EAN-13 codes having 13 characters. These barcodes are widely accepted and recognised globally.

To discover more about our barcodes and there use cases, we have a range of blogs about barcodes that might be of interest.

Advanced encryption keeps your data safe and secure

Advanced encryption keeps your data safe and secure