We have nearly a dozen label manufacturing machines, ranging from the simplest to a digital printing press with laser die cutting capability.

- 1 x EFI Jetrion 4900 digital UV label printing press with inline digital laser die cutting capability

- 1 x MPS EB350 8 colour flexographic printing press

- 1 x Edale Alpha 250 3 colour flexographic press

- 3 x Daco Solutions turreted plain label converters

- 5 x Mark Andy narrow web 3 colour flexo printing presses

- 1 x Tackyboy narrow web single colour flexographic printing press

- 2 x Daco Solutions rewinding and finishing machines

- In-house artwork and plate making capability

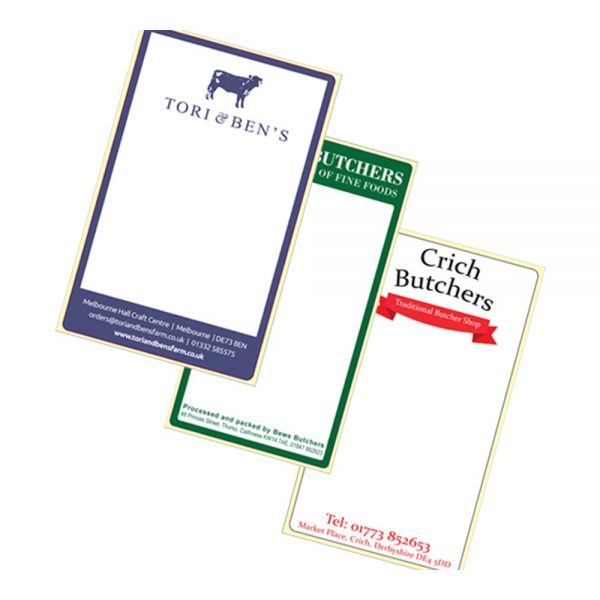

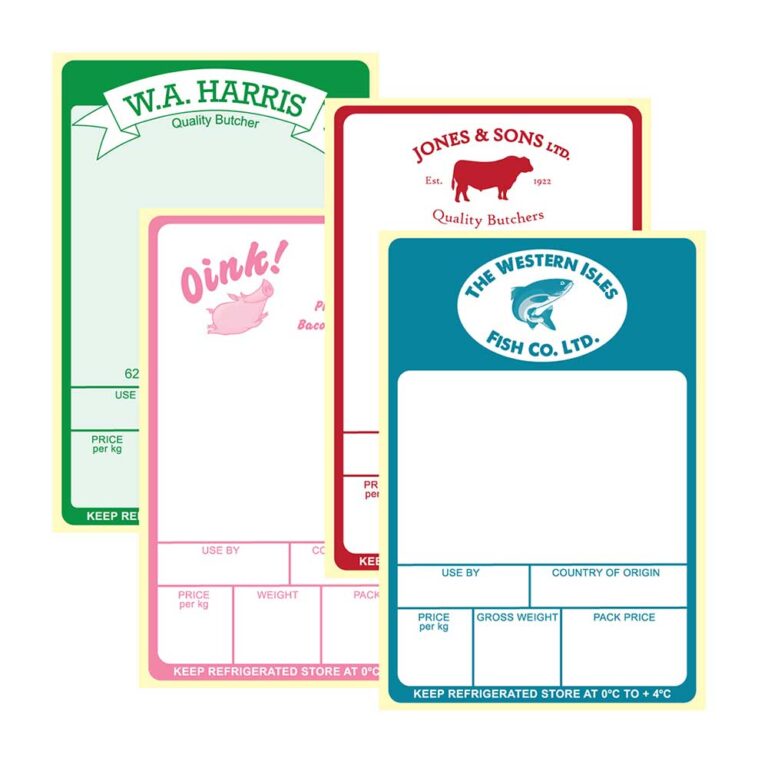

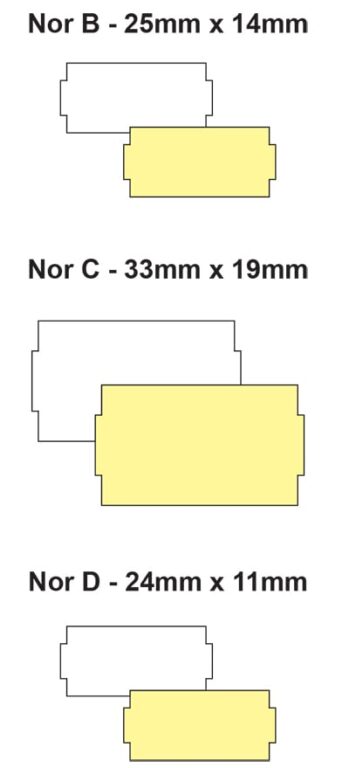

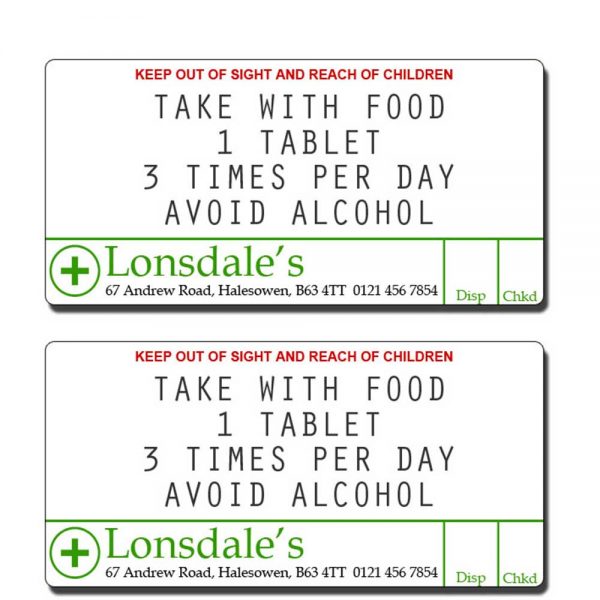

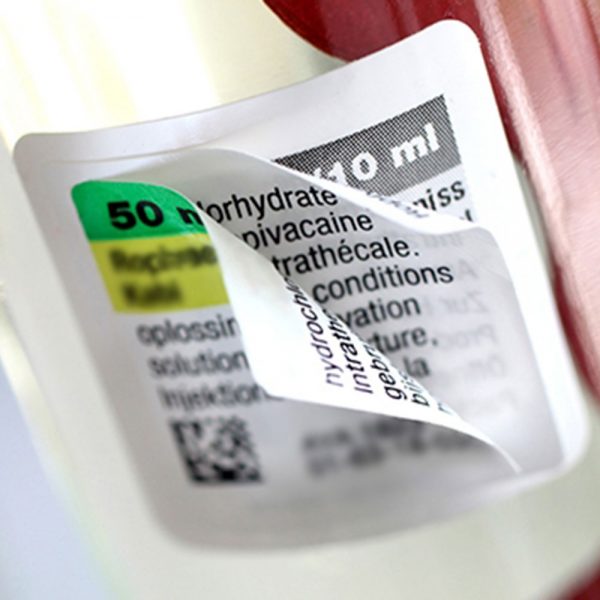

With such a range of equipment at our disposal, product labels of all kinds for all sorts of applications fall into our repertoire. Whether it is sandwich labels, chemical labels, pharmacy labels, food labels or pricing gun labels, we can make them.

As a leading UK label manufacturer, we make buying labels as easy as possible! We will use our wealth of knowledge to come up with the most cost-effective solution for the production of your labels. Whether you need large quantities suited to flexographic printing or digital labels suited to smaller production runs or multiple designs. Speak with an expert now – call 01332 864895

Flexographic Label Production

With nearly 1,000 label manufacturers across the UK, most can only hope to produce the range and quality of label Positive ID Labels thrive on. Unlike over 90% of those competitors, we have both digital and flexographic label production capability. Our flexographic capabilities are of the highest standards thanks to our MPS EB350 printing press. This flexographic label press produces images with crisp image clarity that leaves our competitors in our wake.

Flexographic label production is ideal for large run label orders. Typically, at least 1,000 linear metres of material will be cost effective for a flexographic label order. Flexographic label printing requires printing plates and cutter tooling. These charges are a one-off cost on your first order. The printing plates will cost £35 each and the overall cost depends on the design and specification of the label. We can print up to 8 colours, add lamination or varnishing and print cold foiling to make your labels ‘snap’.

As a flexographic label manufacturer, we also need to cut your labels ‘in-line’ during the print run. We do this using a cutting tool. These vary in cost from around £60 to several hundred pounds, depending on specification. Once the tooling is ordered, any changes to your labels will incur additional tooling charges. However, modern digital label printing has got rid of this issue as both plates and cutters are no longer required!

UK based Digital UK Label Manufacturers

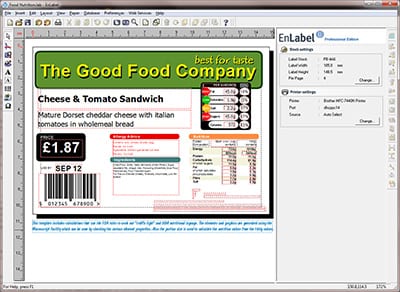

Positive ID Labels is one of the UK’s leading Digital Label Manufacturers. In recent years the UK label manufacturing industry has seen a quantum leap in digital technology for label production. Digital label production offers several benefits when compared to traditional flexographic printing methods.

There are two main types of digital label process used by digital label printing companies. These are toner-based or liquid inkjet-based technologies. Positive ID Labels operate a Jetrion 4900 digital UV inkjet printer with laser die cutting station. Sounds fancy eh? Well, it is!

As a digital label manufacturer, we can take advantage of not requiring fixed printing plates to produce your digital labels. This means we can create a design and print it in much the same way you might on your office or home computer. The only difference is our printer is an industrial high capacity beast!

Not having to buy printing plates is only part of the story. Unlike virtually all UK based digital label printing companies, we have an inline digital laser die cutting station. Whereas other digital label printers will need you to pay for cutter tooling for your labels, we do not. This means our press can produce your labels without the need to buy any tooling whatsoever. There are no initial tooling charges for your order.

Because it is an inline laser die cutting station, your labels are produced in one production sequence. This means we put on the feedstock at one end of the printing press and take off finished rolls of labels on the other! The single-step production process means less cost to us and cheaper labels for you.

Advanced encryption keeps your data safe and secure

Advanced encryption keeps your data safe and secure