UV Inkjet Digital Labels v. Toner Based Digital Labels

Our digital UV inkjet also benefits from very high durability in virtually all environments. UV inkjet digital labels do not suffer from heat issues that toner-based machines can. This is because the ink ‘cures’ onto the label. With toner based machines, the toner is subject to melting at higher temperatures, making it far less durable in many environments. The way to solve that problem is to laminate the output, which adds cost and waste to the production of labels. It can also lead to a high environmental impact to produce your digital labels.

UK Based Plain Label Manufacturer and Blank Label Manufacture

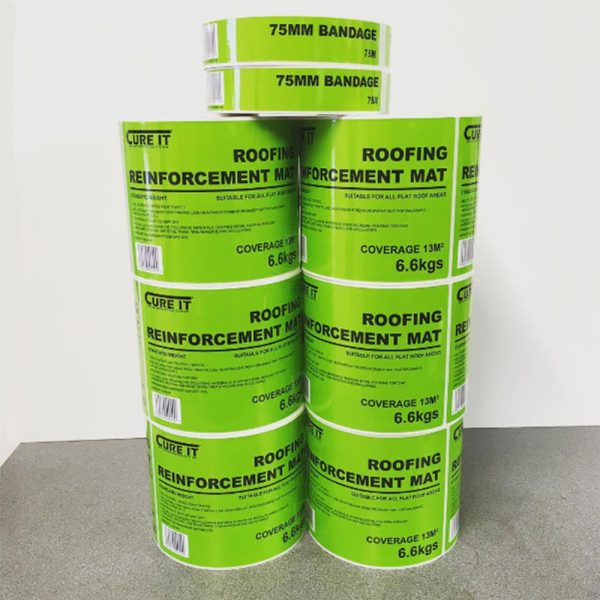

We don’t only print product labels of all types and for all industries using our digital and flexographic printing presses. Positive ID Labels is one of the foremost producers of plain and blank labels for thermal printing systems. We have three Daco Solutions turreted plain label converters with a range of tooling and cutters available for you to use.

- 1 x Turreted Semi-Automatic Daco Solutions PLD350 rotary die cutter

- 2 x Turreted Semi-Automatic Daco Solutions PLD250 rotary die cutter

These machines are the pinnacle of reliability and performance and capable of massive continuous production of plain labels. The larger PLD350 machine incorporates a high capacity unwind, allowing the use of 6,000-meter rolls of feedstock, which reduces downtime and increases throughput. Ideal for the production of courier labels in high volumes, standard 4″x4″ (102mm x 102mm) and 4″x6″ (102mm x 152mm) labels are always in production.

What to Look for in a Custom Label Printing Manufacturer

A. Quality of materials and printing techniques

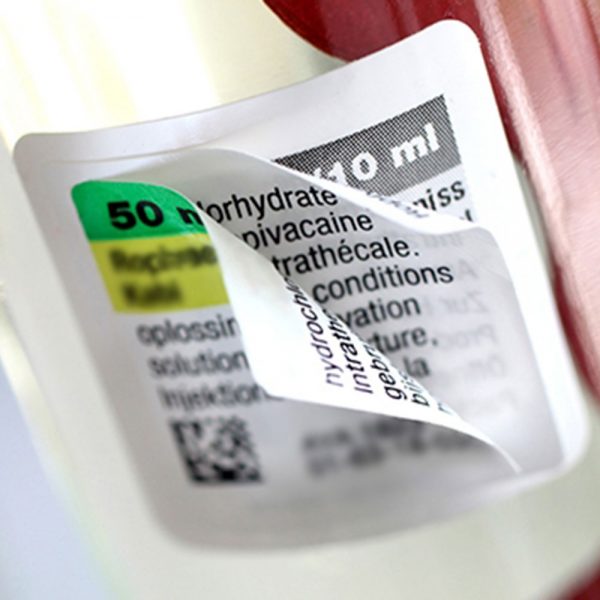

At Positive ID Labels, we only use the best materials to print your labels. This is an essential factor to consider when choosing a custom label printing manufacturer. The durability of the materials used will determine the longevity of the labels, while the printing techniques will impact the overall appearance and legibility of the design. It is important to choose a manufacturer that uses high-quality materials and employs advanced printing techniques to ensure that your custom labels meet your expectations and requirements. Additionally, consider the manufacturer’s reputation for delivering consistent and reliable results to guarantee satisfaction with the final product.

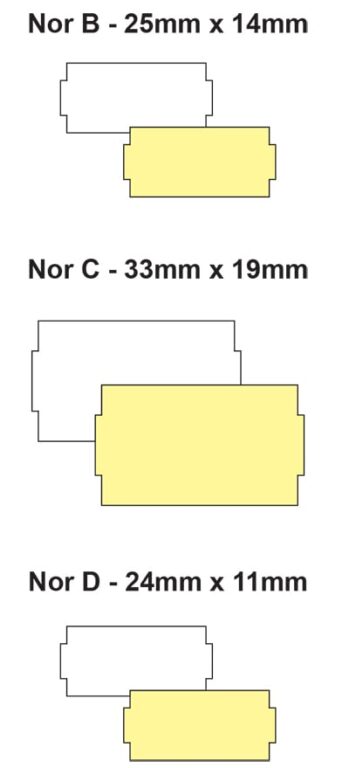

B. Ability to meet specific design and size requirements

Our design service coupled with our flexible printing facilities in South Derbyshire means we can adapt to any printing requirement, large or small, for a huge range of label types. Not all label manufacturers may have the capabilities to produce labels in unique shapes or sizes, so it is important to consider before committing to any one label manufacturer. Make sure to enquire about the manufacturer’s flexibility in accommodating custom requests and their experience in producing labels that match your vision, like we can. By working with a label manufacturer like Positive ID Labels that can meet your specific design and size requirements, you can ensure that the final product will be exactly what you need for your project.

C. Turnaround time and order processing capabilities

We aim to design, print and deliver your labels in under 2 weeks where possible. It’s an important factor to consider when selecting a label manufacturer, as many take much longer. It is crucial to enquire about typical turnaround times for custom orders and the ability to handle large quantities if needed. Additionally, understanding any order processing capabilities, such as their ability to provide rush orders or handle complex shipping requirements, can help ensure a smooth and efficient production process. By carefully evaluating these aspects, you can choose a manufacturer that not only meets your design and size requirements but also delivers your labels in a timely and efficient manner. We deliver on all fronts, so Positive ID should be a logical choice, but ultimately it’s up to you.

Expertise and Knowledge

Expertise and Knowledge

Advanced encryption keeps your data safe and secure

Advanced encryption keeps your data safe and secure